equipment for mechanised tunnelling

Formwork for bridge piers and PULVINums

TUNNEL LINING SOLUTIONS

Euroform produces moulds both for fixed installations and for carousel

systems, for all types of tunnel segments and for any tunnel ring

configuration.

All formworks are designed for easy, safe and durable use.The

regulation system that characterises the Euroform segment moulds

allows full compliance with the tightest tolerances.

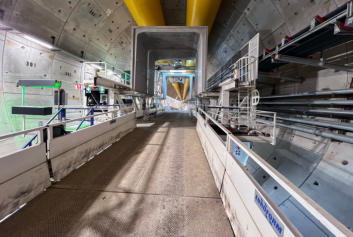

Carousel plants

When it is necessary to regularise the production of tunnel segments, Euroform

provides automated carousel systems.

The carousel system enables precise and consistent execution times to be

achieved for each task, thanks to highly efficient cycles.

Carousel plants also allow for a reduction in manpower, more efficient use of

space and increased safety.

equipment for conventional tunnelling

Each tunnel has its own diameter, cross-section, and geological composition. To achieve maximum precision in

lining each one, Euroform can provide the tailor-made solution that best meets the project’s requirements, thanks

to a complete portfolio of formwork and service gantries.

Bypass, niche and collar formworks

Slab formwork

Service gantries

Both the bridge pier formwork and the bridge pulvinum formwork are designed to speed up moulding and

demoulding operations by using a modular system of interconnected shutters.

Segment handling devices

Depending on the customer’s needs, Euroform supplies all types of equipment for the handling of tunnel

segments in production segments in production plants.

Special equipment

Every project has its own challenges that require special solutions, and Euroform responds to the customer’s

needs by providing whatever is required.

Segment demolding and tilting clamps

Segment tilting tables

Multi-segment transfer trolleys

Vacuum segment handling devices

Concreting buckets

Concrete distributor with vibrating screed

Steam production plant

Self-reacting formwork

The self-reacting tunnel formwork makes it possible to cast the tunnel vault

quickly and accurately, even for tunnels of considerable length. In fact, there is

no need for anchoring to the ground or to the quayside, which simplifies mould

and demoulding operations.

Self-supporting formwork

The self-supporting tunnel formwork reduces lateral movement during

concreting by anchoring to the base. Anchoring can be achieved using tyloops on

the quay or a stop system on the ground.

Modular formwork for different cross-section tunnels

Invert formwork

For the lining of multiple tunnels, each with its own cross-profile, Euroform offers a

modular formwork system that can be quickly and easily reconfigured for different

sections.

Its modular design allows the same formwork to be used for several tunnels

with no structural modifications. Simply reassemble the formwork according

to the required layout, reducing procurement, transport, and storage costs.

The tunnel bypass formwork has a self-propelled transport system that ensures

high manoeuvrability even in the confined spaces typical of this type of

formwork, combined with fast transfer from one casting to the next.

Niche and collar tunnel formworks are easy to install and can be supplied with

fast handling systems.

The tunnel slab formwork can have the typical single-table configuration for one

casting at a time, or multiple tables linked together with a tail-to-head sector

transfer system, allowing continuous concreting operations of considerable

length without having to wait for the last cast slab to set.

The invert tunnel formwork is typically self-supporting and can be self-erecting

where necessary.

In addition to the typical multi-level configuration, the membrane gantry can be

fitted with a hydraulically operated man basket for easy and safe membrane

installation.

The curing gantry allows direct control of temperature and humidity levels with

continuous data logging.

The reinforcement gantry allows reinforcement to be placed safely and easily

with reduced manpower.

segment moulds, Conventional formwork and service equipment for tunnel

lining

Euroform designs and manufactures high-quality formwork and service equipment for the construction of tunnels

using both mechanised and conventional techniques. Accuracy in planning and design, in the manufacture and

adjustment of the equipment, and in the inspection of the final product enables us to achieve the highest

standards of quality and precision.

Fullround formwork

The fullround tunnel formwork has a completely circular cross-section to enable

the entire tunnel cross-section to be cast in a single pour. It is made up of

interconnected longitudinal sectors with a telescopic configuration that allows

the rear sector to be dismantled, transported in front of the leading sector and

reassembled, thus allowing continuous pouring.

© Euroform S.r.l., all rights reserved

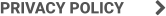

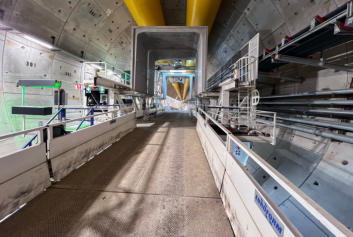

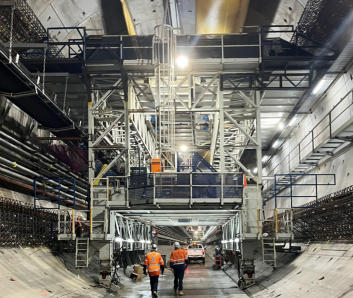

COMPLEMENTARY EQUIPMENT FOR MECHANISED EXCAVATION

Euroform also offers a complete range of additional equipment for the lining of tunnels with mechanised

excavation.

For tunnels that require the passage of services and vehicles in a secondary tunnel

within the main one, Euroform proposes the ISIG, a self-propelled bridge that

transports the prefabricated culvert segments and positions them to create the

service tunnel.

The ISIG is independent of the TBM and does not interfere with the excavation

process

.

Internal Structure Installation Gantry (ISIG)

The formwork is transported by a gantry that moves directly on the

tunnel-lining segments.

The gantry can carry the formwork for both the road deck and the smoke

evacuation duct.

Formwork for slab support corbel

The gantry travels on the tunnel-lining segments.

The scabbling and drilling units are mounted on specially designed platforms.

Scabbling and drilling gantry

The gantry is driven straight over the tunnel-lining segments.

A very large storage area for the reinforcement bars allows them to be laid

quickly and easily.

Rebar installation gantry

The gantry is equipped with a crane system that enables the installation of service

pipes and their supports.

The large, high-capacity storage area is optimally organised to facilitate all

handling operations.

Pipe installation gantry

The gantry moves on self-installed rails.

A cantilever arm picks up the prefabricated slabs and places them on the corbels.

The same arm can install the slabs of the road deck

and the smoke evacuation duct.

Slab installation gantry

Segment moulds

equipment FOR MECHANISED TUNNELLING

Formwork for bridge piers and PULVINUMs

TUNNEL LINING SOLUTIONS

Euroform produces moulds both for fixed installations

and for carousel systems, for all types of tunnel

segments and for any tunnel ring configuration.

All formworks are designed for easy, safe and durable

use.The regulation system that characterises the

Euroform segment moulds allows full compliance with

the tightest tolerances.

Carousel plants

When it is necessary to regularise the production of

tunnel segments, Euroform provides automated carousel

systems.

The carousel system enables precise and consistent

execution times to be achieved for each task, thanks to

highly efficient cycles.

Carousel plants also allow for a reduction in manpower,

more efficient use of space and increased safety.

equipment for conventional tunnelling

Each tunnel has its own diameter, cross-section, and geological composition.

To achieve maximum precision in lining each one, Euroform can provide the

tailor-made solution that best meets the project's requirements, thanks to a

complete portfolio of formwork and service gantries.

Bypass, niche and collar formworks

Slab formwork

Both the bridge pier formwork and the bridge pulvinum formwork are designed

to speed up moulding and demoulding operations by using a modular system

of interconnected shutters.

Segment handling devices

Depending on the customer's needs, Euroform supplies all types of equipment

for the handling of tunnel segments in production segments in production plants.

Special equipment

Every project has its own challenges that require special solutions, and Euroform

responds to the customer's needs by providing whatever is required.

Segment demolding and tilting

clamps

Segment tilting tables

Multi-segment transfer trolleys

Vacuum segment handling

devices

Concreting buckets

Concrete distributor with

vibrating screed

Steam production plant

Self-reacting formwork

The self-reacting tunnel formwork makes it possible to

cast the tunnel vault quickly and accurately, even for

tunnels of considerable length. In fact, there is no need

for anchoring to the ground or to the quayside, which

simplifies mould and demoulding operations.

Self-supporting formwork

The self-supporting tunnel formwork reduces lateral

movement during concreting by anchoring to the base.

Anchoring can be achieved using tyloops on the quay or

a stop system on the ground.

Fullround formwork

The fullround tunnel formwork has a completely circular

cross-section to enable the entire tunnel cross-section to

be cast in a single pour. It is made up of interconnected

longitudinal sectors with a telescopic configuration that

allows the rear sector to be dismantled, transported in

front of the leading sector and reassembled, thus

allowing continuous pouring.

Modular formwork for different cross-section tunnels

Invert formwork

For the lining of multiple tunnels, each with its own

cross-profile, Euroform offers a modular formwork system

that can be quickly and easily reconfigured for different

sections.

Its modular design allows the same formwork to be used

for several tunnels with no structural modifications. Simply

reassemble the formwork according to the required layout,

reducing procurement, transport, and storage costs.

The tunnel bypass formwork has a self-propelled

transport system that ensures high manoeuvrability even

in the confined spaces typical of this type of formwork,

combined with fast transfer from one casting to the next.

Niche and collar tunnel formworks are easy to install and

can be supplied with fast handling systems.

The tunnel slab formwork can have the typical single-table

configuration for one casting at a time, or multiple tables

linked together with a tail-to-head sector transfer system,

allowing continuous concreting operations of considerable

length without having to wait for the last cast slab to set.

The invert tunnel formwork is typically self-supporting

and can be self-erecting where necessary.

Service gantries

In addition to the typical multi-level configuration, the

membrane gantry can be fitted with a hydraulically

operated man basket for easy and safe membrane

installation.

The curing gantry allows direct control of temperature and

humidity levels with continuous data logging.

The reinforcement gantry allows reinforcement to be

placed safely and easily with reduced manpower.

Euroform designs and manufactures high-quality formwork and service

equipment for the construction of tunnels using both mechanised and

conventional techniques. Accuracy in planning and design, in the manufacture

and adjustment of the equipment, and in the inspection of the final product

enables us to achieve the highest standards of quality and precision.

segment moulds, Conventional formwork and service equipment

for tunnel lining

© Euroform S.r.l., all rights reserved

COMPLEMENTARY EQUIPMENT FOR MECHANISED EXCAVATION

Euroform also offers a complete range of additional equipment for the lining of

tunnels with mechanised excavation.

For tunnels that require the passage of services and

vehicles in a secondary tunnel within the main one,

Euroform proposes the ISIG, a self-propelled bridge that

transports the prefabricated culvert segments and

positions them to create the service tunnel. The ISIG is

independent of the TBM and does not interfere with the

excavation process

.

Internal Structure Installation Gantry (ISIG)

The formwork is transported by a gantry that moves

directly on the tunnel-lining segments.

The gantry can carry the formwork for both the road deck

and the smoke evacuation duct.

Formwork for slab support corbel

The gantry travels on the tunnel-lining segments.

The scabbling and drilling units are mounted on specially

designed platforms.

Scabbling and drilling gantry

The gantry is driven straight over the tunnel-lining

segments.

A very large storage area for the reinforcement bars allows

them to be laid quickly and easily.

Rebar installation gantry

The gantry is equipped with a crane system that enables

the installation of service pipes and their supports.

The large, high-capacity storage area is optimally

organised to facilitate all handling operations.

Pipe installation gantry

The gantry moves on self-installed rails.

A cantilever arm picks up the prefabricated slabs

and places them on the corbels.

The same arm can install the slabs of the road deck

and the smoke evacuation duct.

Slab installation gantry

Segment moulds

Formwork for bridge piers and PULVINUMS

TUNNEL LINING SOLUTIONS

Euroform produces moulds both for fixed installations and

for carousel systems, for all types of tunnel segments and

for any tunnel ring configuration.

All formworks are designed for easy, safe and durable use.

The regulation system that characterises

the Euroform segment moulds allows full compliance with

the tightest tolerances.

Carousel plants

When it is necessary to regularise the production of tunnel

segments, Euroform provides automated carousel

systems.

The carousel system enables precise and consistent

execution times to be achieved for each task, thanks to

highly efficient cycles.

Carousel plants also allow for a reduction in manpower,

more efficient use of space and increased safety.

equipment for conventional tunnelling

Each tunnel has its own diameter, cross-section, and

geological composition. To achieve maximum precision in

lining each one, Euroform can provide the tailor-made

solution that best meets the project's requirements, thanks

to a complete portfolio of formwork and service gantries.

Bypass, niche and collar formworks

Slab formwork

Service gantries

Both the bridge pier formwork and the bridge pulvinum

formwork are designed to speed up moulding and

demoulding operations by using a modular system of

interconnected shutters.

Segment handling devices

Depending on the customer's needs, Euroform supplies all

types of equipment for the handling of tunnel segments in

production segments in production plants.

Special equipment

Every project has its own challenges that require special

solutions, and Euroform responds to the customer's needs

by providing whatever is required.

Segment demolding and

tilting clamps

Segment tilting

tables

Multi-segment transfer

trolleys

Vacuum segment

handling devices

Concreting buckets

Concrete distributor with

vibrating screed

Steam production

plant

Self-reacting formwork

The self-reacting tunnel formwork makes it possible to

cast the tunnel vault quickly and accurately, even for

tunnels of considerable length. In fact, there is no need for

anchoring to the ground or to the quayside, which

simplifies mould and demoulding operations.

Self-supporting formwork

The self-supporting tunnel formwork reduces lateral

movement during concreting by anchoring to the base.

Anchoring can be achieved using tyloops on the quay or a

stop system on the ground.

Fullround formwork

The fullround tunnel formwork has a completely circular

cross-section to enable the entire tunnel cross-section to

be cast in a single pour. It is made up of interconnected

longitudinal sectors with a telescopic configuration that

allows the rear sector to be dismantled, transported in

front of the leading sector and reassembled, thus allowing

continuous pouring.

Modular formwork for different cross-section tunnels

Invert formwork

For the lining of multiple tunnels, each with its own

cross-profile, Euroform offers a modular formwork system

that can be quickly and easily reconfigured for different

sections. Its modular design allows the same formwork to

be used for several tunnels with no structural modifications.

Simply reassemble the formwork according to the required

layout, reducing procurement, transport, and storage costs.

The tunnel bypass formwork has a self-propelled transport

system that ensures high manoeuvrability even in the

confined spaces typical of this type of formwork,

combined with fast transfer from one casting to the next.

Niche and collar tunnel formworks are easy to install and

can be supplied with fast handling systems.

The tunnel slab formwork can have the typical single-table

configuration for one casting at a time, or multiple tables

linked together with a tail-to-head sector transfer system,

allowing continuous concreting operations of considerable

length without having to wait for the last cast slab to set.

The invert tunnel formwork is typically self-supporting and

can be self-erecting where necessary.

In addition to the typical multi-level configuration, the

membrane gantry can be fitted with a hydraulically

operated man basket for easy and safe membrane

installation.

The curing gantry allows direct control of temperature and

humidity levels with continuous data logging.

The reinforcement gantry allows reinforcement to be

placed safely and easily with reduced manpower.

Euroform designs and manufactures high-quality formwork

and service equipment for the construction of tunnels using

both mechanised and conventional techniques.

Accuracy in planning and design, in the manufacture and

adjustment of the equipment, and in the inspection of the

final product enables us to achieve the highest standards of

quality and precision.

segment moulds, Conventional formwork and

service equipment for tunnel lining

equipment FOR MECHANISED TUNNELLING

© Euroform S.r.l.

COMPLEMENTARY EQUIPMENT FOR MECHANISED

EXCAVATION

Euroform also offers a complete range of additional

equipment for the lining of tunnels with mechanised

excavation.

For tunnels that require the passage of services and

vehicles in a secondary tunnel within the main one,

Euroform proposes the ISIG, a self-propelled bridge that

transports the prefabricated culvert segments and positions

them to create the service tunnel.

The ISIG is independent of the TBM and does not interfere

with the excavation process

.

Internal Structure Installation Gantry (ISIG)

The formwork is transported by a gantry that moves directly

on the tunnel-lining segments.

The gantry can carry the formwork for both the road deck

and the smoke evacuation duct.

Formwork for slab support corbel

The gantry travels on the tunnel-lining segments.

The scabbling and drilling units are mounted on specially

designed platforms.

Scabbling and drilling gantry

The gantry is driven straight over the tunnel-lining segments.

A very large storage area for the reinforcement bars allows

them to be laid quickly and easily.

Rebar installation gantry

The gantry is equipped with a crane system that enables the

installation of service pipes and their supports.

The large, high-capacity storage area is optimally organised

to facilitate all handling operations.

Pipe installation gantry

The gantry moves on self-installed rails.

A cantilever arm picks up the prefabricated slabs and places

them on the corbels.

The same arm can install the slabs of the road deck and

the smoke evacuation duct.

Slab installation gantry

Segment moulds